Have A Info About What Are The Three Different Types Of Cutting Processes Pictures Long Kinky Twist Hairstyles

Cnc lathes and turning machines.

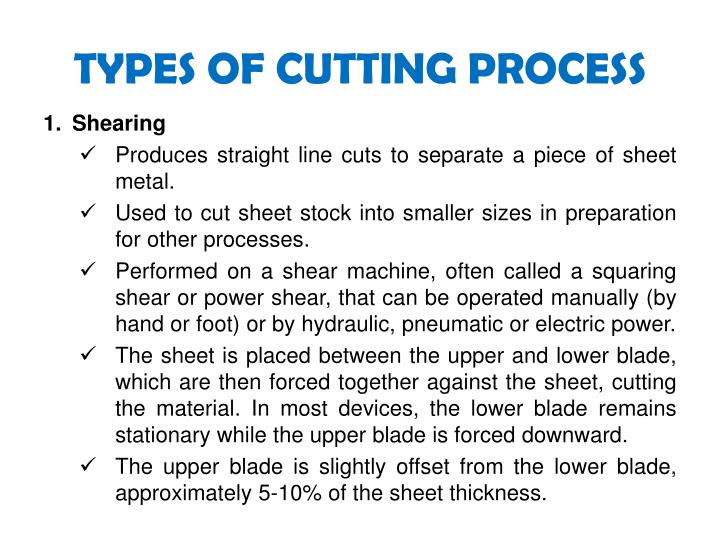

What are the three different types of cutting processes. Turning is a machining method that uses a lathe to rotate the metal while a cutting tool moves linearly to remove metal along the diameter, creating a cylindrical. Cutting processes fall into one of three main categories: It has a secure connection to the machine tool.

Types, properties, and applications of cutting tool material. This article looks at the machine processes of turning, drilling, milling, grinding, planning, sawing, broaching, electrical discharge machining, and electro chemical machining. Cnc electrical discharge machines (edm) cnc waterjet cutting machine.

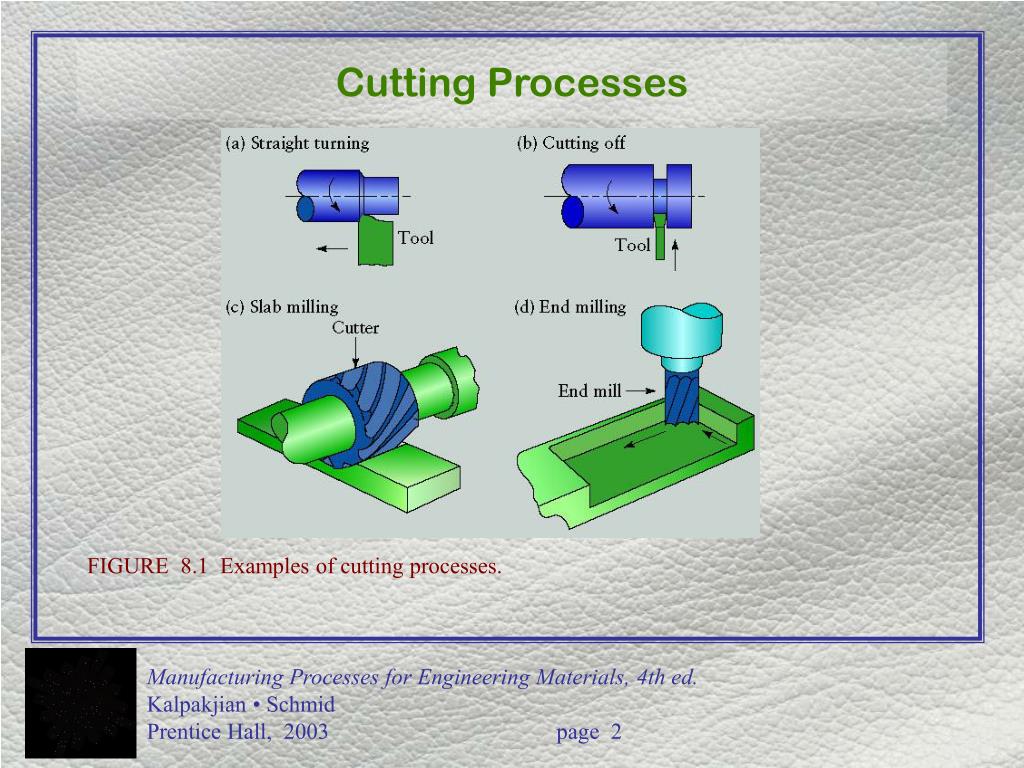

Cutting can be broadly divided into two methods: The different types of metal cutting processes are more diverse than you can expect, and makes use of a variety of industrial machines in the philippines. Abrasive cutting methods include operations such as grinding, lapping, and waterjet cutting.

(b) velocity diagram in the cutting zone. There is more than one common type of cnc machine due to the many different cnc machine processes, such as milling, drilling, laser cutting, edm cutting, lathe work, and more. Cutting is a technique where the operator moves a material (workpiece) such as metal and the tool in relation to each other in order to shape the workpiece into the desired form through shaving, drilling, etc.

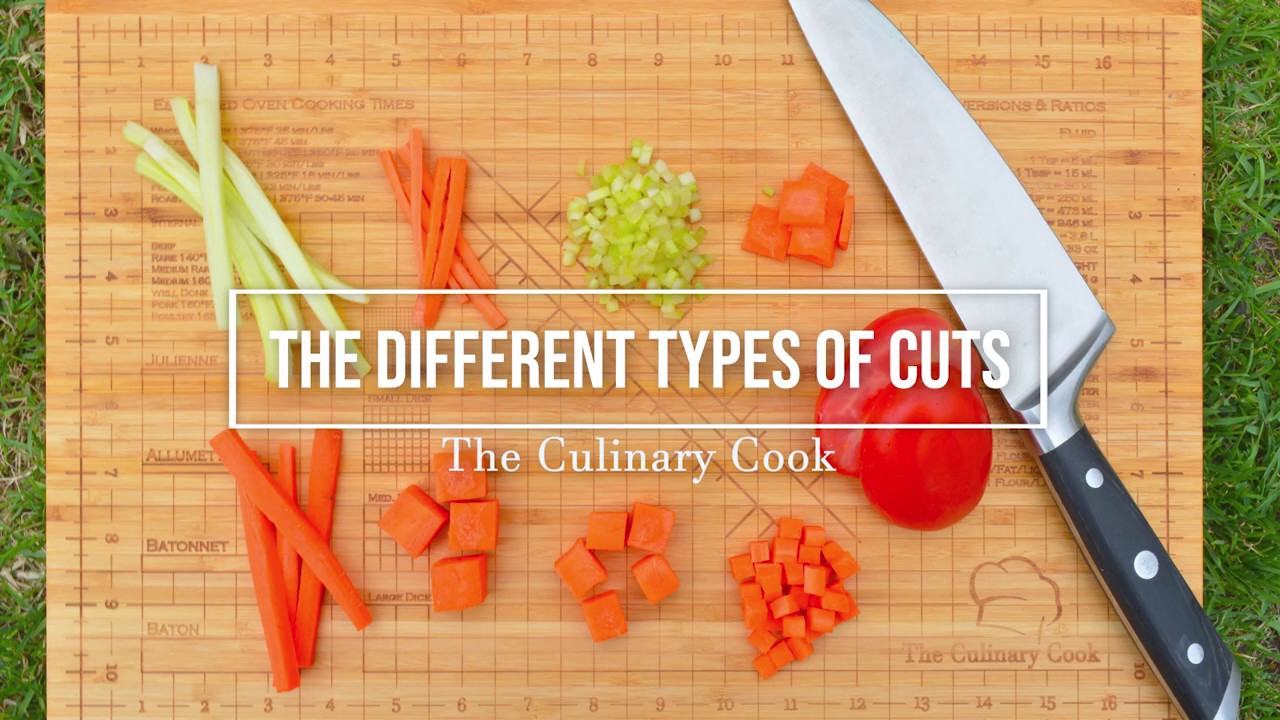

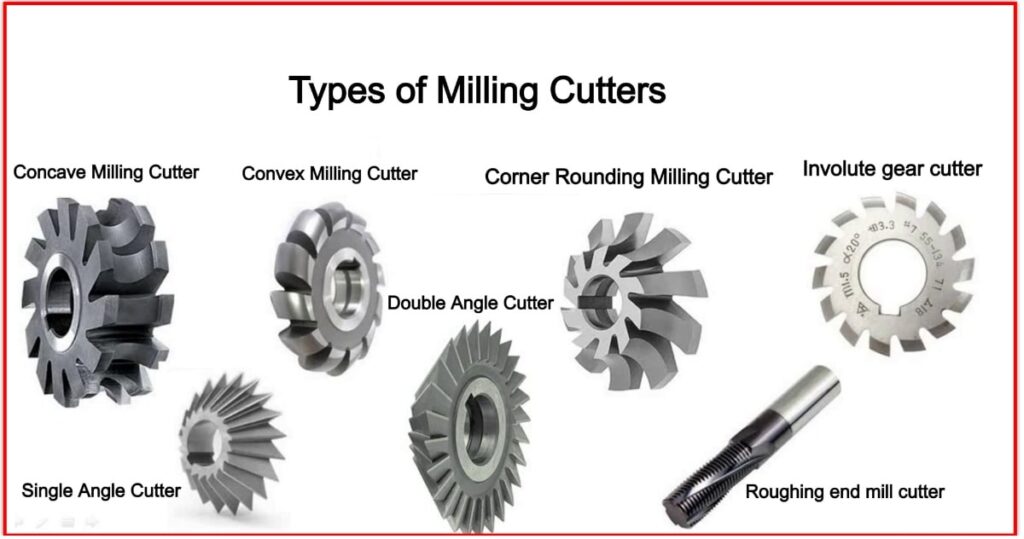

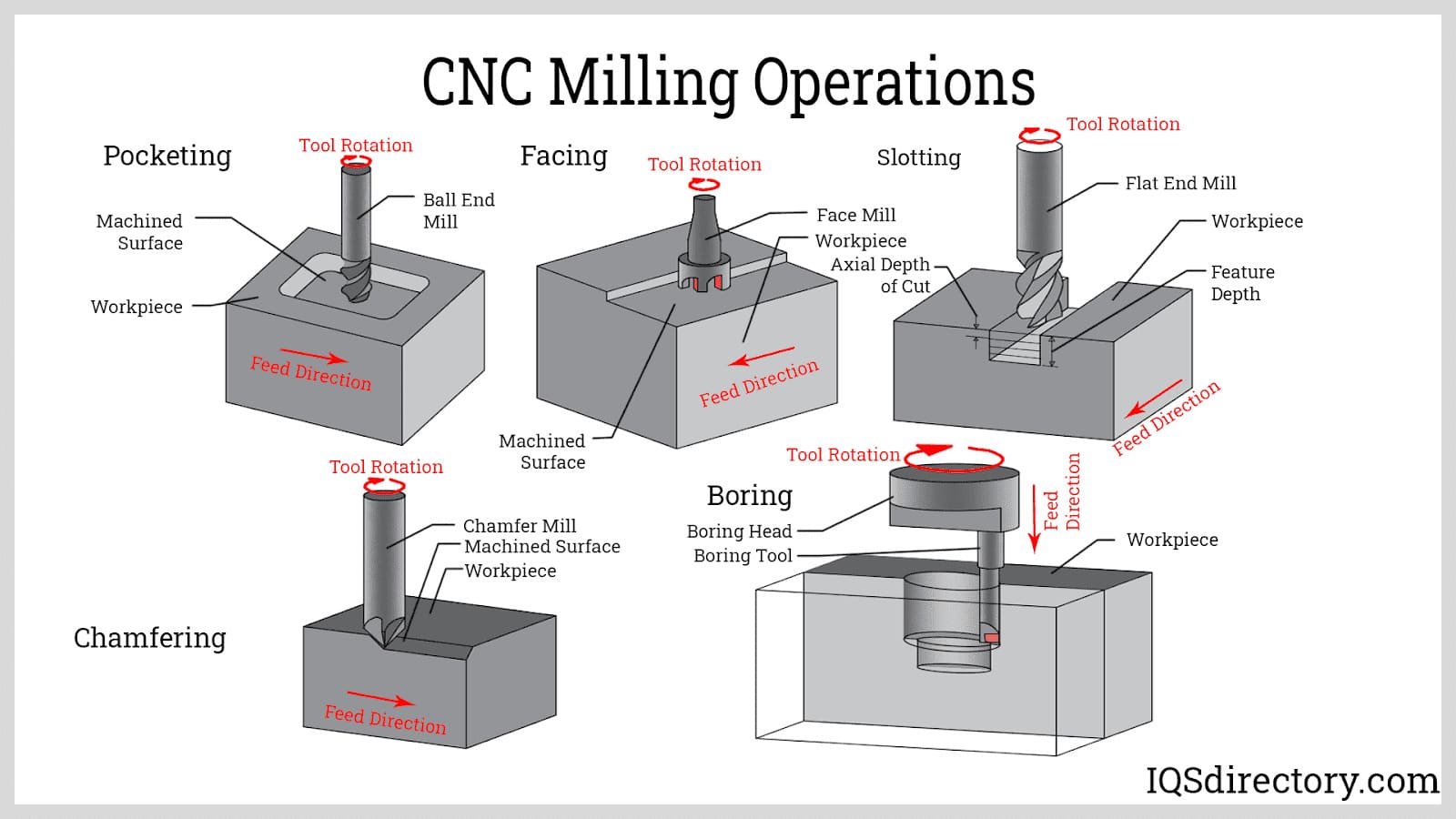

There are other processes that also fall into the category of machining, but when it comes to modern machining processes, turning, milling, and drilling cover the majority. This very common type of metal fabrication is the cutting of a workpiece to split it into smaller sections. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

V=> cutting velocity, vs= shear velocity, vc=chip velocity φ= shear angle, α=rake angle. There are two main types of machining operations; Type of cut, i.e., continuous (turning, boring etc.) or intermittent cut (milling).

Claude excels at tasks involving language, reasoning, analysis, coding, and more. Claude is a highly performant, trustworthy, and intelligent ai platform built by anthropic. There are different types of milling processes, such as face milling, end milling, slot milling, form milling, gear cutting, and more.

While sawing is the oldest method of cutting, modern methods include laser cutting, waterjet. Introducing claude 3.5 sonnet, our most intelligent model yet. Technology has made it easier to cut metal into.

These operations are much faster than heat processes like edm & laser, offer better edge quality, and typically provide some sort of cost savings for manufacturers. What are the different types of metal cutting processes? There are three main kinds of machining:

Understanding the various types of machining processes is crucial for anyone involved in manufacturing, engineering, or design. Material used for machine tools, gauges, press and press tools, jigs, and fixtures. Tool material can be divided into two types:

/culinary-arts-knife-cuts-photo-gallery-4121795-Final-ea725152bf5b4b20ab49fa1e083a9496.png)